Brazil

LYNX Process integrated two of Navtech's mining radar sensors into their stacker-reclaimer system to profile the stockpile close to the bucket wheel, where dust and weather are unavoidable and high-resolution sensing is required. With the radar data being used in their volumetric calculations, bucket wheel cut optimisation, and collision avoidance, the automation system enabled by Navtech's technology has driven improvements in safety and productivity.

Reliable data for anti-collision system.

LYNX Process, an automation system integrator based in Brazil, collaborated with its end customer at the Minas Gerais mine to address specific challenges encountered in the stacker-reclaimer machine operations. The primary goal was to enhance safety and efficiency by automating the system. One critical requirement was obtaining a high-resolution profile of the stockpile, both pre- and post-cut of the bucket wheel. This data would play a crucial role in several operations, namely feeding information into the anti-collision system, optimising the bucket wheel cut, minimising air scooping, preventing stockpile collapses, and reducing the stress on the machine’s structure. Additionally, when combined with the boom’s position, the profile data could contribute to volumetric calculations of the stockpile.

Initially, LYNX positioned a laser scanner at the apex of the machine. However, it lacked robustness in harsh weather and dusty conditions. Given the mine’s grimy environment, Lynx needed a sensor close to the bucket wheel. The system had to operate seamlessly in various situations, ranging from heavy monsoon weather to dust, and endure vibrations and shocks without interruptions. Limited access to the sensors posed an additional challenge, making regular cleaning and maintenance impossible. Laser scanners were ruled out due to susceptibility to dirt on the lens, potential degradation, and the need for frequent servicing every two years. Alternative radar sensors on the market presented their own challenges, including having a limited field of view, low angular resolution, and restricted access to raw data.

“For nearly a decade, we have worked alongside Navtech Radar as a partner and, in that time, they have been very supportive, approachable, and flexible. The ability to access their sensors’ raw data has been a key part of enabling us to support various mining applications and has opened up new opportunities for us in the mining industry, such as the stockpile monitoring application and autonomous operation.”

Tárik Simão

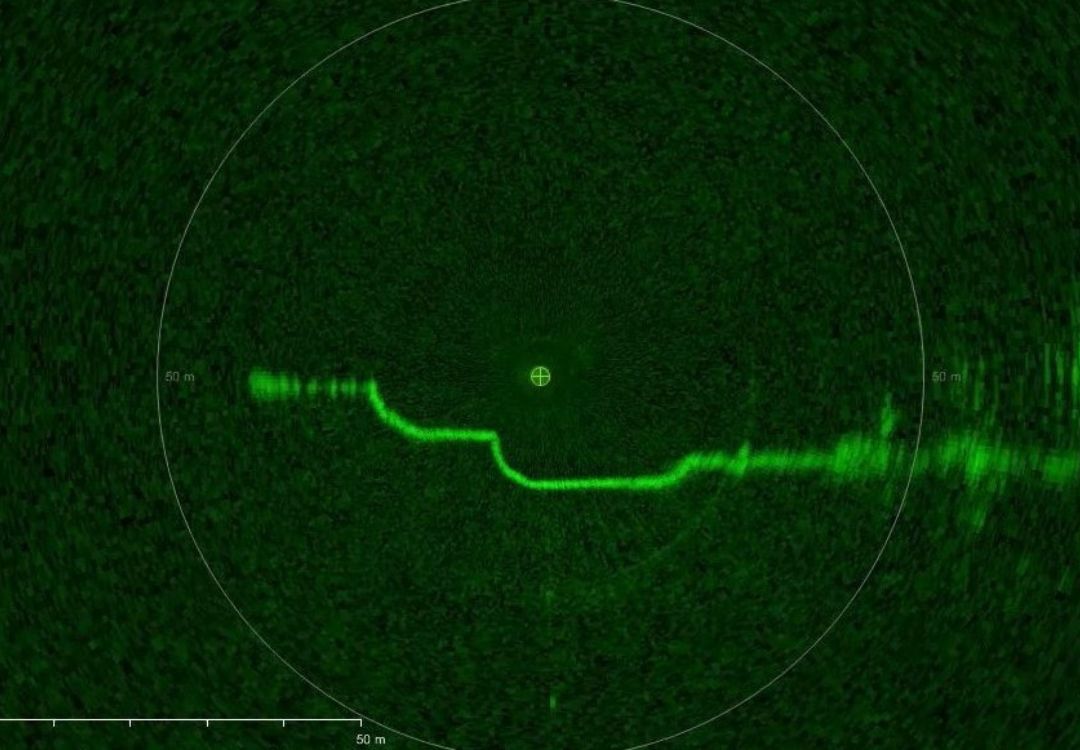

To overcome these challenges, LYNX opted for a solution involving two of Navtech’s industrial radar sensors per machine, mounted to provide a clear line of sight to the stockpile, close to the bucket wheel. The chosen radar sensors offered a 360° field of view, eliminating the need for multiple sensors and reducing wiring and calibration complexities.

With a fast update rate of 4Hz, high angular resolution (0.9 degrees), and high-range resolution (4cm), the radar sensors provided high-quality data. LYNX selected Navtech’s radar sensors, leveraging millimetre radio waves with a longer wavelength than visible light as used in Lidars or laser scanners. The longer wavelength allowed radar signals to penetrate obstacles like dust, fog, rain, and extreme weather conditions, ensuring uninterrupted profiling even when the sensors were covered in dust or dirt.

The raw radar data was fed into an algorithm for accurate profiling (range and bearing points) of the stockpile from the perspective of the radar. These radar sensors seamlessly integrated into LYNX’s anti-collision system, volumetric calculation, and bucket wheel cut optimisation module. Boasting a maintenance-free operational life, the Navtech radar sensors could go 100,000 hours without cleaning. Additionally, LYNX’s automation engineers benefited from an open software development kit (SDK), facilitating streamlined integration and early evaluation of the system.

Recently, LYNX and its end customer upgraded from the original CIR radar sensors to the Robust Automation Sensor (RAS) sensor family, an enhanced version introduced in 2022, further solidifying the system’s performance and reliability. This successful implementation showcases the power of robust radar technology in optimising mining operations for safety and efficiency.

The implementation of the automated vehicles, coupled with Navtech’s radar sensors, has delivered a shift in the mining operations, achieving a commendable zero accident record involving personnel.

With an 8% boost in machine productivity, the end-user has significantly reduced overflows, enhancing predictability and curbing machine wear. The transition to a controlled environment, eliminating on-board operators, has further streamlined processes.

Notably, the environmental impact is evident in a 10% reduction in operational overflows, aligning with ESG goals. There has also been a 90% drop in operational deviations underscores the transformative impact.

Minas Gerais